At H Brettell & Sons Ltd

Rob Brettell, fifth generation in the family wood-turning business

Contributing Photographer Alex Pink & I made a trip over to Forest Gate recently to visit H Brettell & Sons Ltd, one of the East End’s most venerable wood working companies, founded in 1830 in Haggerston by Henry Brettell, a descendant of a long line of Huguenot cabinet makers.

“What I am known for is square wood turning,” announced Rob Brettell – the current incumbent – once he had led us through the large and picturesque ramshackle factory, with ivy growing through the roof, and up into the loft where he stores the precious examples of his handiwork. At first, I thought Rob might be having me on, as I always understood that wood turning was – by its very nature – round. Yet I discovered I was mistaken, as Rob produced finely-turned banisters and spindles that were square – it was a style I recognised from seventeenth century staircases. “Everyone asks how we do it?” he informed me before I had the chance to open my mouth, “but I’m not going to tell you.”

Unable to pursue this line of enquiry, I commented upon the extravagant greenery intruding through the ceiling. “We call that the hanging gardens of Brettells,” Rob quipped amiably, casting his restless eye around the stockroom and lifting a mallet with a disproportionally long handle, rather like a polo stick. It was a hammer for beating out copper stills in the distilling industry, I learnt. Grabbing an ash stake of arcane design that appeared to be an oar without a paddle, Rob explained that this was a lever used by the Ministry of Defence for prising heavy cargo out of aeroplanes, giving us a vivid demonstration.

Boxes of handmade mallets, shiny and round, drew our attention next and took Rob back to his childhood. “I started at nine in my school holidays,” he admitted to me, “sweeping up the woodchips and banging mallets together, for pocket money. At twelve, I was turning spindles but I had to stand on a box to set up the rotary knife.” The lathe that Rob learned on was acquired by the company in 1916 and is still in use today.

Before the use of plastic became widespread, there was hardly any endeavour that did not require a product made by Brettells. Jewellers used beech handled engraving tools, sat upon traditional three-legged stools and filed rings on wooden bench pegs. Glass merchants cut glass with diamond-tipped cutters in rosewood handles. Brewers used rattan long-handled floggers. The Royal Navy platted rope with Lignum Vitae fids. The Post Office used boxwood date stamps. Pubs had beech lemon boards and rosewood beer pump handles. Judges had wig stands. Morticians used mallets. Wilkinson’s needed sword scabbards. Ronson required lighter bases. And so it went on.

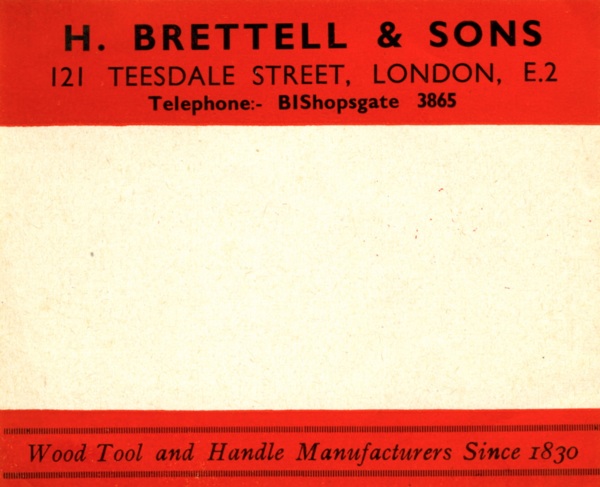

The first Henry Brettell began making tool handles out of scrap timber acquired from the sawmill, where he had workshop in the corner of the yard, in Haggerston. In 1912, his son who was also called Henry, bought a former bakery in Teesdale St, Bethnal Green. Manufacturing for the Ministry of Defence in two wars, Brettells thrived by producing chair legs and table legs throughout the twentieth century. Moving to Forest Gate after the Teesdale St factory was compulsorily purchased for demolition in the fifties, Brettells acquired more rotary lathes and moved over towards the production of stair parts as the furniture industry waned. Today their work is increasingly bespoke, turning spindles to order and specialising in elaborate serpentine wooden hand rails and scrolls created with an expertise no-one else can match.

“I think I’m very lucky – I enjoy working and doing stuff that most people can’t do,” Rob confessed to me proudly, “I have an appetite for a challenge, I say ‘yes’ to a job and then I have to work out how to do it. I can do anything except make a lot of money.”

Henry Brettell who founded the company around 183o, pictured with his second son Will – “They used to throw chisels each other in competition over who would take over the company from their father”

Ellen, Henry junior, James and Henry Brettell senior

Henry James Brettell “Everyone’s got all their fingers here, except grandfather”

Goldstein Hand Turning Lathe

James Bretell

Rob Brettell – “What I am known for is square wood turning”

Square-turned spindles

New photographs copyright © Alex Pink

H Brettell & Sons Ltd, 20-24 Chestnut Avenue, Forest Gate, E7 OJH

You may also like to read about

Good to know there’s another one around.

I should explain: there’s a similar, but much smaller establishment in Milton Rd, Walthamstow. ( I think they were previously in High Street )

Good to see that some craftsmen are still making their beautiful things. Valerie

Amazing story about an early idea to fill a market gap in fine craft. — But HOW do they manage the square wood turning???

Love & Peace

ACHIM

I know that I would love the smell in this establishment. My father and grandfather came from a long line of shipwrights and both spent hours in their workshops making all sorts of items from wood so I grew up with the smell of freshly sawn timber and varnishes, wonderful memories which you have revived for me with this fascinating account. Thank you.

Lovely, I can smell the wood shavings….

Brilliant set of pictures. Thanks for posting this.